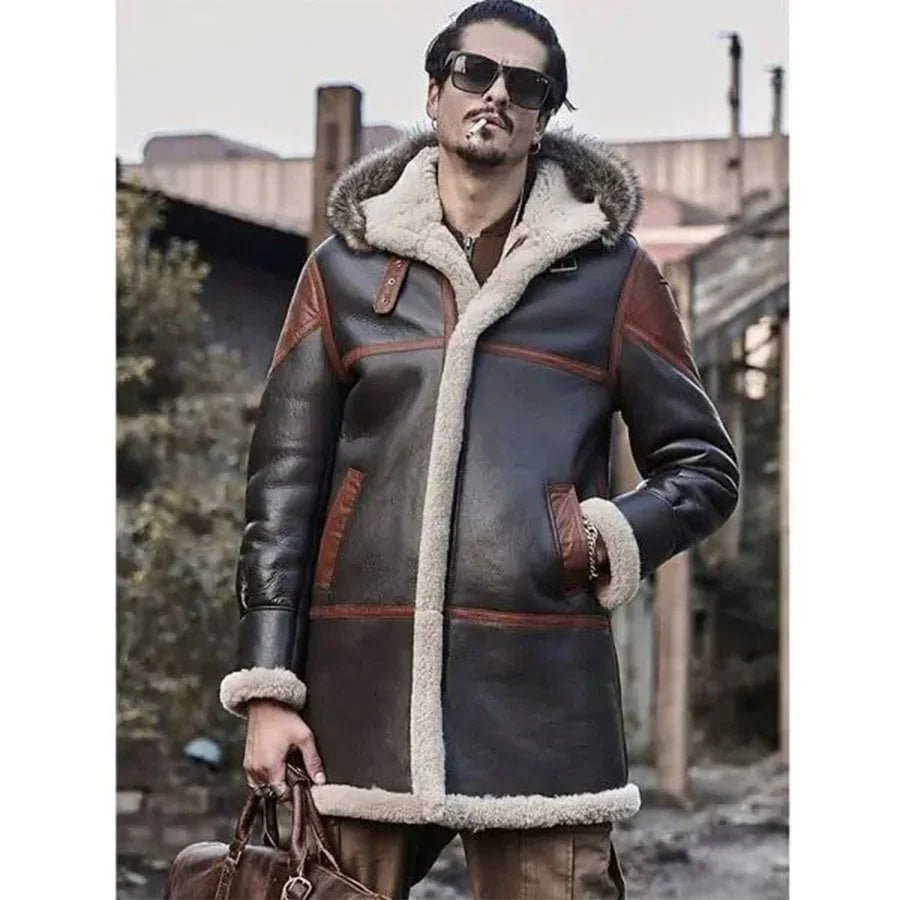

How Sheepskin Shearling Coats Are Made ?

Sourcing the Sheepskin: The Journey Begins

The journey of creating a sheepskin shearling coat starts with the meticulous sourcing of high-quality sheepskin. This process begins with the selection of specific sheep breeds known for their superior hides. Breeds such as Merino, Texel, and Suffolk are highly favored. Each of these breeds offers unique characteristics that contribute to the texture and durability of the sheepskin. Merino, for instance, is celebrated for its softness and warmth, making it a prime choice for luxury shearling coats.

Geographic regions also play a significant role in the quality of sheepskin. Countries like New Zealand, the United Kingdom, and Australia are renowned for their exceptional farming practices and high-quality wool production. These regions provide optimal environments that support the health and well-being of the sheep, ensuring that the resulting hides are of the finest grade.

Humane farming practices are paramount in the production of sheepskin shearling coats. Ethical considerations ensure the animals are treated with care, provided with ample space to graze, and maintained under conditions that promote their overall health. Regular health check-ups and proper nutrition contribute to the quality of the sheepskin, as healthy sheep produce healthier, more resilient hides.

The shearing process is executed with precision to guarantee the wool is harvested without causing harm to the sheep. This method entails removing the fleece in one piece, which is then processed to transform it into the luxurious material used in fashion. The health and maintenance of the sheep are directly linked to the quality of the skin, highlighting the significance of ethical and sustainable farming.

Overall, the initial steps in creating a sheepskin shearling coat encompass more than just selecting any sheepskin; they involve a comprehensive approach centered on breed selection, regional advantages, and ethical farming practices. This foundational phase sets the stage for the high-quality craftsmanship further down the production line.

Tanning and Processing: Transforming Raw Skins

The transformation of raw sheepskin into durable, supple leather is an intricate process that begins with the careful preparation of the raw skins. Once the skins are removed from the sheep, they undergo a series of initial treatments aimed at preservation. This typically involves cleaning and salting the skins. The cleaning stage removes debris, while salting helps to prevent the growth of bacteria, ensuring the skins remain intact until further processing.

After the initial preservation, the sheepskins are soaked to rehydrate them, making it easier to proceed with the fleshing step. Fleshing involves the removal of any remaining flesh and fat, which, if left, could cause the leather to deteriorate. This is an essential step as it prepares the sheepskin for the tanning process, which will determine the final quality of the leather.

Tanning is the heart of the transformation process, wherein raw sheepskins are chemically stabilized to become leather. There are various methods of tanning, with the most common involving the use of chromium salts for chrome tanning. This method is known for producing a soft and durable end product. However, there is also a natural method known as vegetable tanning, which uses tannins found in tree bark and other plant sources. Vegetable-tanned leather is known for its sturdy, long-lasting qualities and the unique patina it develops over time.

The environmental impacts of tanning cannot be overlooked. Traditional tanning processes have been associated with significant ecological footprints, primarily due to the use of chemicals like chromium salts. In response, the industry has seen innovations in eco-friendly tanning methods. These include the use of environmentally safe chemicals and the development of closed-loop systems that recycle water and reduce waste. Such advances not only minimize environmental damage but also meet the growing consumer demand for sustainable fashion.

Through these meticulous stages of tanning and processing, raw sheepskins are transformed into the luxurious and durable leather that forms the basis of timeless shearling coats. By refining traditional methods and embracing modern, eco-conscious innovations, the sheepskin industry continues to balance quality craftsmanship with environmental responsibility.

Crafting the Coat: Design and Assembly

The creation of a sheepskin shearling coat begins with a meticulous design process. Skilled fashion designers start with an initial concept, often inspired by contemporary trends, seasonal needs, or historical styles. The concept is transformed into detailed sketches that outline every aspect of the coat’s dimensions, features, and aesthetic elements. These sketches serve as the blueprint for the entire crafting process.

Upon finalizing the sketches, pattern makers develop precise patterns. These patterns are essential as they dictate the arrangement and size of each section of the leather and shearling materials. Particular attention is paid to ensuring that the layout maximizes the utilization of the premium sheepskin, minimizing waste while preserving quality.

Once the patterns are ready, expert artisans cut the leather and shearling with exacting precision. This step is crucial because any deviation can affect the final fit and look of the garment. The artisans’ expertise ensures that each piece fits together seamlessly, maintaining the integrity of the design.

The assembly of the sections involves sophisticated bonding techniques. The layers of sheepskin and shearling are bonded together using specialized methods that ensure a durable connection without compromising the material’s flexibility. This phase is followed by the sewing process, which is equally important for the coat’s overall strength and fluid movement. High-quality threads and reinforced stitches are employed to withstand daily wear and tear, while still providing comfort and ease of movement.

Beyond the basic structure, decorative elements and hardware add the finishing touches to the sheepskin shearling coat. Hardware, such as zippers, buttons, and buckles, are sourced for their durability and aesthetic appeal. Decorative stitches, embroidery, and other adornments are carefully incorporated to enhance the coat’s visual appeal, making each piece unique and reflective of the brand’s craftsmanship.

Final Touches: Quality Control and Finishing

The final stages in the creation of sheepskin shearling coats are pivotal in ensuring that each coat meets the high standards expected by discerning consumers. The quality control process begins with a meticulous inspection to identify any potential defects. Skilled inspectors examine the stitching carefully, ensuring that each seam is robust and uniform. This scrutiny extends to checking the leather integrity, ensuring there are no imperfections or inconsistencies in the material that could compromise the coat’s durability or aesthetic appeal.

Next, the focus shifts to overall craftsmanship. Each coat is reviewed for symmetry and finish, verifying that the design specifications have been rigorously followed. Any discrepancies, no matter how minor, are addressed at this stage to ensure that only flawless products make it to the next step. The trimming process is also crucial, where excess material is removed, creating a smooth and polished look that enhances the garment’s sleek profile.

Once the initial quality checks are completed, additional treatments are applied to augment the coat’s functionality and longevity. Waterproofing treatments are commonly used, offering a protective layer that ensures the sheepskin shearling coat can withstand various weather conditions while maintaining its luxurious feel. Labels are carefully added, providing a final touch of branding and authenticity that reassures customers of the coat’s origin and quality.

The final phase involves packaging and distribution. Each coat is packaged with care, utilizing materials that protect the garment during transit. The packaging must be both functional and appealing, reflecting the high quality of the product inside. The labeled and packaged coats are then sent to various distribution channels, ensuring that upon reaching the customer, the product is in pristine condition, maintaining the excellence that has been instilled from the very beginning of its production journey.