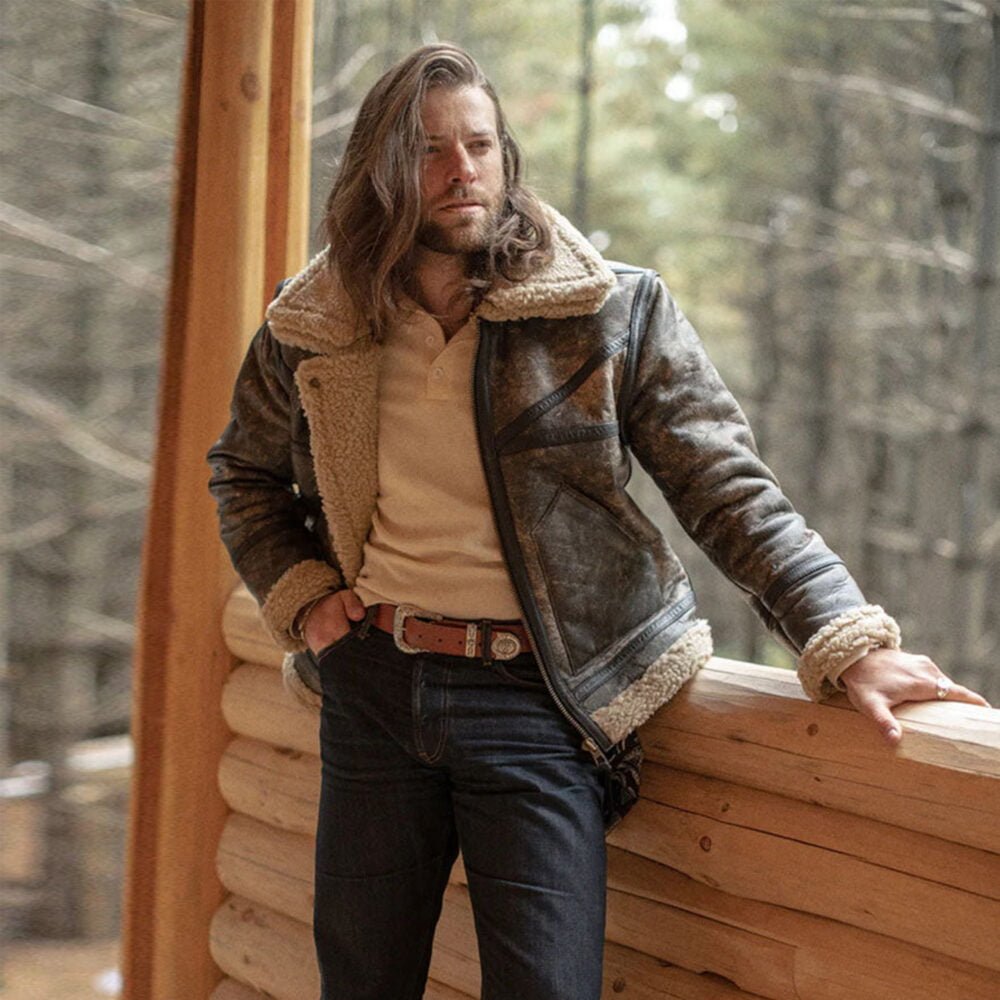

How to Make a Shearling Jacket?

Materials and Tools Needed

Creating a shearling jackets requires a meticulous selection of materials and tools to ensure both the quality and durability of the final product. The primary material for a shearling jacket is the shearling hide itself, which can be lambskin or sheepskin. When selecting shearling, it is crucial to consider its softness, thickness, and flexibility, as these attributes significantly impact the comfort and wearability of the jacket. High-quality shearling should have a supple texture, consistent thickness, and minimal blemishes.

In addition to the shearling hide, you will need various supplementary materials. Lining fabric is essential for the interior of the jacket, providing additional warmth and comfort. Choose a lining that complements the shearling in both color and texture. Zippers are another critical component, and it’s advisable to use heavy-duty metal zippers for durability. Thread must be strong and resilient to withstand the thicker material of shearling; polyester or nylon threads are recommended for their durability and strength.

The tools required for constructing a shearling jacket are specialized to handle the unique properties of the material. A heavy-duty sewing machine is indispensable, preferably one that can manage thick layers of material without skipping stitches. Needles designed specifically for leather and heavy fabrics are necessary to penetrate the dense shearling hide. Cutting tools, such as rotary cutters or heavy-duty shears, ensure clean and precise cuts.

Safety precautions are paramount when working with shearling. Always use a cutting mat to protect surfaces and ensure stability while cutting. Wearing protective gloves can prevent accidental cuts and abrasions. Adequate ventilation is necessary when working with adhesives or treatments to avoid inhaling fumes. By assembling the right materials and tools and adhering to safety guidelines, you set the foundation for crafting a high-quality shearling jacket.

Step-by-Step Construction Process

Constructing a shearling jacket involves several meticulous steps, each requiring precision and attention to detail. The initial phase begins with preparing the shearling hide, which includes properly cutting and shaping the material. Begin by laying out the hide on a flat surface and carefully marking the pattern pieces with a fabric marker. Ensure that the markings align with the grain of the hide for consistency and durability.

Once the pieces are marked, use a sharp cutting tool to cut along the lines. It’s essential to cut slowly and steadily to avoid any uneven edges. After cutting, shape the pieces as needed, particularly around curves and corners, to ensure they fit together seamlessly during assembly.

Next, start assembling the jacket by focusing on the shoulders. Align the shoulder pieces and use a sturdy stitch, such as a backstitch or a saddle stitch, to join them. Make sure the seams are secure and even. Once the shoulders are attached, move on to the sleeves. Position the sleeve pieces and attach them to the shoulder seams, ensuring that the seams are smooth and lie flat.

After the sleeves, proceed to assemble the body of the jacket. Join the front and back panels at the side seams using a durable stitch. Pay close attention to aligning the seams to ensure a professional finish. Following the body assembly, it’s time to attach the collar. Align the collar piece with the neckline, and stitch it in place, ensuring the edges are even and secure.

Inserting the lining is the next crucial step. Cut the lining fabric according to the pattern and attach it to the inside of the jacket, starting with the sleeves and moving to the body and collar. Use a slip stitch to secure the lining, making sure it lies flat and smooth.

Finally, insert the zippers. Position the zipper along the front opening and use a zipper foot attachment on your sewing machine to stitch it in place. Ensure the zipper operates smoothly without catching on the fabric. For a professional finish, treat the edges with a leather edge treatment solution to prevent fraying, and make any final adjustments to ensure a perfect fit.

Throughout the construction process, refer to visual aids such as diagrams or reference images to guide you. These can help clarify complex steps and ensure accuracy in your work. By following these detailed instructions and taking the time to perfect each step, you can create a high-quality shearling jacket.